|

Most conversions are cheap and

easy. Advantages are quicker starting, cheaper parts, common

12volt batteries and lamps. The only negative is if you are

a showman. A 1948 JD-M did not come from the the factory with

an alternator and you will lose points if you have one.

The alternator is not the only

cost. If you have lights, you will have to install new 12v

bulbs. Ignition coils will have to be replaced or a ballast

resistor will have to be added to tractors with distributors. Ammeters,

tachs, oil pressure gauges should not be affected, unless lighted.

The old 6volt starter will be fine.

Eventually, we will have enough

examples here so you can convert with just about anything you have

around the shop.

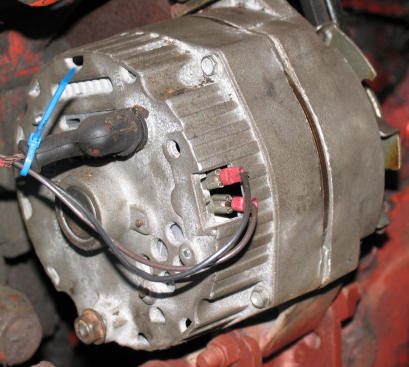

If you have to buy, we recommend

the Delco / Chevy 10SI. Tell your parts guy you want one for

a '72 El Camino. Then tell him you need a single or double

pulley. Usually a single is what you want. In some cases,

you might want to go with a one wire version. It is usually

the easiest, but costs a little more. We have bought both versions

locally and on eBay.

As for brackets, they are not too

hard to adapt or fabricate. Usually some pipe or washers will

do. If not, you can find custom conversion brackets on eBay.

|